Data mining

HTM System Solutions has developed an IoT-system for rock drilling rigs developed by LKAB Wassara. The system is in use in LKABs mine in Malmberget.

How can we help you with your challenges?

Background

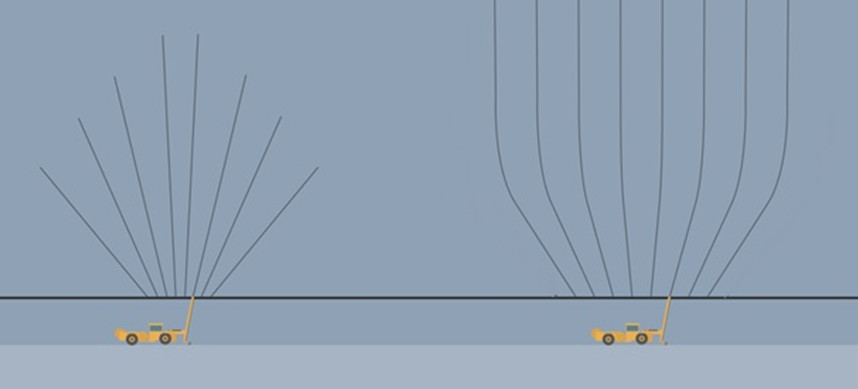

LKAB Wassara AB is a subsidiary of LKAB with operations in Huddinge and Malmberget. The company is developing water-powered drilling systems used in, among other applications, LKABs iron ore production. One step in the iron ore production is drilling blast holes which are later filled with a blasting agent. After the blast the ore falls down in the production tunnel and is hauled out.

When the blast holes are straight the length are limited by the distance between them in the outer end of the fan. When the distance becomes to large the ore fragmentation after a blast becomes suboptimal. If the blast holes instead are made parallel the length can be increased without increasing the distance between them. In this way every hole fan can result in more ore.

To be able to create parallel blast holes, LKAB, in cooperation with LKAB Wassara, is now creating a new type of rig which can control the drilling in real time. The drill system is not made up of straight rods like on a traditional rig but of a steel pipe on a coil that is winded up as the drill penetrates the rock.

IoT-project

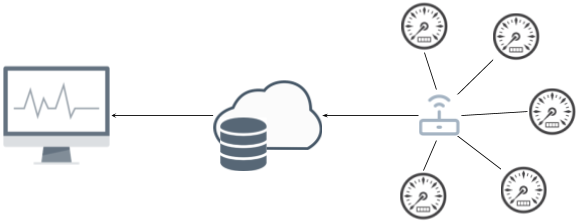

A rock drill rig under operation creates large amounts of data från different sensors and control systems. HTM System Solutions is helping wassara to build a system which collects and analyses information valuable for both rig development and ore production purposes. In the short term the collected data will mainly be used for the rig development but in the longer run the intention is to utilize the data in the iron ore production process.

HTM has designed and implemented a system which has the capacity to reliably collect data from several rigs in full operation. Wassaras engineers can now in real time supervise what is happenings on the rig and see how it behaves during drilling. Analysis can also be performed on historical data.

Both real time and historical data can be plotted and analyzed

Software and project files can be remotely updated

Users can subscribe to events to get notifications